The flooring at the pharmaceutical Industry facility can be protected by applying a special coating. Many businesses in the drug industry use epoxy flooring to increase cleanliness and thus the safety of their products and workplaces.

Businesses that make or sell drugs are required to have flooring that can stand up to oils, acids, and solvents. Most of the time, these kinds of businesses have to deal with the chemicals listed above regularly. Epoxy floor coatings are also resistant to abrasion and impacts, which is a very important quality since the floors of plants are often walked on and hit by heavy machinery and vehicles.

Epoxy flooring is a type of floor that lasts a long time and doesn’t wear down easily. Epoxy flooring can be put on top of concrete floors to give them both a high level of performance and a nice look.

For a pharmaceutical building to have a surface that is hard, shiny, and lasts for a long time, it needs to have fully cured epoxy flooring. Epoxy flooring is so versatile that it gives benefits in every aspect, from the initial installation to the ongoing upkeep.

Call our professional epoxy contractors today at (209) 879-9674.

Advantages of epoxy flooring in the Pharmaceutical Industry:

1. Hygiene

A contaminant-free environment is necessary for the production of life-saving medicines and drugs. So, hygienic flooring is a vital component of such an environment.

Epoxy flooring surpasses the hygiene requirements for laboratories and prevents the growth of microorganisms that could compromise the testing and development of pharmaceuticals. Additionally, epoxy flooring is available in a variety of colors and patterns.

The majority of general flooring installations only provide an antimicrobial sealer in the top layer, which means that the protection it offers will be rendered useless if the floor is gouged or chipped. In contrast, the epoxy flooring that we provide for the pharmaceutical business is designed to fully permeate the floor to provide superior protection against a broad range of bacteria, yeast, and fungi.

2. Clean Surface that is Easy to Clean

Home depot epoxy is applied in one continuous layer, thus unlike tile or other forms of flooring, it does not have seams, joints, or ridges. Because of this, epoxy is a more sanitary alternative for flooring, as it does not have any cracks or crevices in which dirt and bacteria could potentially hide.

3. Long-Lasting Floors

Epoxy flooring is made of epoxy resins and hardeners, which are both thermosetting resins. Epoxy resin is a thermosetting resin because it forms cross-polymer structures that are tightly connected and can keep a lot of hardness and stickiness.

When epoxy is used to cover a floor, the result is often a surface that lasts a long time and doesn’t wear down easily.

4. Chemically Resistant Floors

Resins and hardeners are mixed to make epoxy floors. This creates a chemical bond that hardens into a stiff, durable plastic that is resistant to many chemicals. You won’t be able to scratch or stain these floors either. Warehouses that make chemicals, like those in pharmaceutical companies and other chemical factories, must be resistant to the chemicals they use.

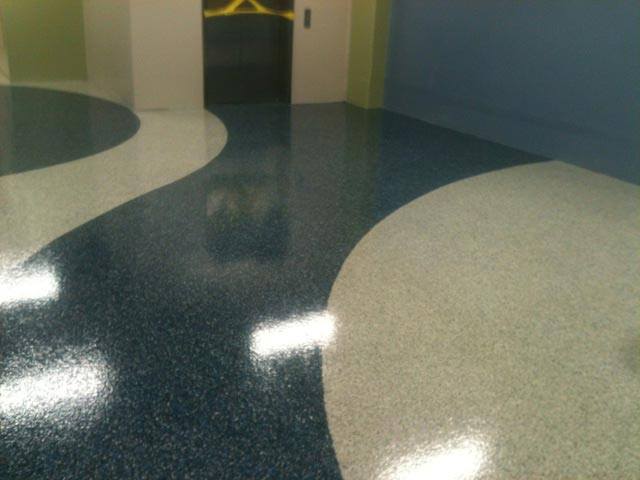

5. Provides an Aesthetic and Visually Appealing Floor Surface

Epoxy flooring comes in many different colors and patterns, so it can be changed to fit the needs of each client or the style of the building as a whole.

6. Improved safety

Adding epoxy flooring to a work area makes the area safer. Because epoxy flooring is resistant to heat, fire, and slipping, these floors are safer in general. Epoxy floors are shiny so a lot of light bounces off of them. This makes the whole storage building brighter.

7. Strength

In terms of flexural strength, the majority of epoxy floors are more than 3x as strong as concrete, which typically has a rating of fewer than 3,000 pounds per square inch (psi).

Epoxy flooring is designed to endure intense temperatures, heavy gear, and large volumes of foot traffic, all of which are common in the food processing industry. Epoxy flooring is incomparably more durable than any other option.

8. Epoxy Flooring for Pharmaceutical Firms Boost Productivity

Epoxy flooring in pharmaceutical companies can help boost productivity.

Resina epoxy flooring in a warehouse will make it easier for vehicles and equipment to move around, make the space brighter, and make it easier for workers to see what they are doing.

Reach our professional epoxy contractors today at (209) 879-9674.

Maintenance Costs for Floors are Low

Epoxy flooring is easy to install and doesn’t need much maintenance, even if there are cracks and holes in the surface. Epoxy flooring can be very long-lasting, so it probably won’t need much upkeep. Because of this, the overall cost of epoxy flooring is less than having a normal concrete floor.

10. Bacteria-free floor solution

Normal flooring will have nooks and crannies where bacteria and other microorganisms can grow. Bacteria can grow more easily on floors that are hard to clean, but this won’t happen with an epoxy floor solution. Epoxy floors are easy to clean and stop bacteria from growing. Epoxy flooring works well in places like stores and factories.

From its labs to its assembly lines, the pharmaceutical industry is at the forefront of scientific progress in every way. Diverse Technology Industrial Inc. understands that. When it comes to doing epoxy flooring for pharmaceuticals, we are the best in the business. You can benefit from our many years of experience.

For a pharmaceutical company, selecting the right flooring might be a tricky proposition. There is a lot more to consider than just hygiene when it comes to laboratories and production lines. In addition to being long-lasting, chemical-resistant, and supportive of a sterile working environment, the flooring you select should also be highly durable.

For pharmaceutical quality assurance, the Food and Drug Administration (FDA) has set severe requirements. As a result, facilities are regularly inspected and penalized for failing to comply with severe laws. So, pharmaceutical companies need to choose sturdy epoxy flooring solutions that can withstand these rigorous standards.

Diverse Technology Industrial Flooring can provide high-quality flooring systems for the r pharmaceutical industry that are chemically resistant, durable, and safe.

Call (209) 879-9674 to learn more about our effective, hard-wearing floor solutions for pharmaceutical plants in the United States.